This year I’ve been all over the place creatively and, well, so has life in general. I didn’t seem to get much done at times, but when I look closer that was because I tackled single projects that took up a lot of time. I did a bit of sewing, a bit of weaving, delved into some occasional crafts like jewellery-making and air-dry clay, finished some long-term WIPs and culled several kinds of hobby supplies. It feels like my mind began to jump from hobby to hobby in the latter months of the year, new shiny things taking my attention before I’d finished with whatever had last attracted me, as if Covid 19 gave me some king of creative ADHD.

January & February:

The Print & Paint With Natural Dyes workshop took up all of my creative energy at the beginning of the year, partly because so much else were going on, including having Dad and his very naughty cat staying with us.

March:

Using the knowledge I’d gained in the workshop, I painted/dyed three tops and a scarf. I also sewed a shirt out of a sarong.

April:

I didn’t include the Ink-Making workshop in my 2022 summary, but I think I should have. Six months after, I made some more inks as some sources dependant on season became available.

May:

A bit more sewing happened, first when I turned Motto Skirt into a top…

… and made a Chambray Dress.

And I returned to the loom to finish the Bouclé Chains Scarf.

June:

I finished a coiling fabric basket, made while visiting Mum.

More exploration of Deflected Doubleweave with bouclé yarn happened with the Baroque Scarf.

I also culled my mosaic supplies and did an illustration commission.

July:

And another DDW project finally using a design I drafted a few years ago: the Electricity Scarf.

August:

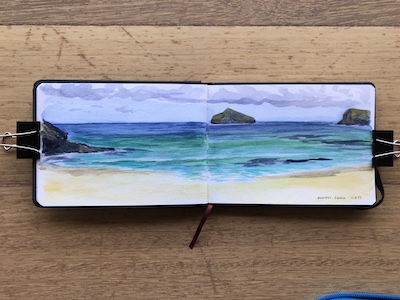

We went to Lord Howe Island, and I did some sketches.

September:

The fourth and favourite DDW bouclé scarf: Copper Roses.

I tried making watercolour paint, and felt a bit ‘meh’ about it.

October:

A bout of finishitis set in. I lengthened Slinky Ribs and made it all rib:

We went to Norfolk Island on an artist holiday.

A bout of Covid 19 somehow led to me culling things. First my jewellery collection, which led to jewellery-making.

November:

I finally, at long last, finished the Pin Loom Blanket.

I wove a Honeycomb Scarf and Tapestry Beret.

The jewellery-making also included a dive into air dry clay.

I finally, at long last, finished the dishcloths that had been on the Jane loom for a year.

December:

Watching Project Runway and The Great British Sewing Bee had me itching to sew. After culling my sewing materials, I made Paul a bucket hat and me some shorts.

And then got the itch to crochet. This Granny Beret seemed a good warm up to something bigger.

A big yarn cull moved the flannelette strips meant for rag rugs into the fabric stash intended for quilts. I sewed a single bed sized quilt.

Also:

This year was also the year of the artist subscription box. I tried one Paletteful Pack but decided against signing up because the postage was too expensive, then gave SketchBox a go and stuck with it. They proved to be a very entertaining and interesting monthly treat. It allowed me to try some art supplies I’ve never encountered before. It’s likely after a year I’ll stop the subscription because there are only so many kinds of art supply so the rewards will eventually diminish, but it has been fun and I suspect I’ll miss it if I do.

I also did a lot of oil painting, mostly in the plein air group but also lots of still life both at the art society and at home. I decided to stop posting pictures of my art, however, until it was clearer how plagiarism software (AI) was going to affect everything.