I’ve been sewing a dress. Progress has been a bit slow due to a non-flu illness that stole a week, and doing the construction in small steps due to the pattern being rather fussy. On the weekend I decided I would finish it. I picked up a skirt front and moved to the window for better light, so I could see which was the right side and instead saw little spots of white. Then I looked closer.

Holes. Tiny holes.

So I picked up the other skirt pieces. One had holes, the others were fine. The bodice with the finicky instructions… a hole in a complicated front panel.

Ok, I had bought the fabric cheap. Clearly this was why it had been discounted. The main reason I’d bought the fabric was to test patterns with since I wasn’t all that keen on the colour. So not a huge disaster. But I would have skipped some of the fussy sewing instructions if I’d known. Too fussy to unpick the bodice and replace the holey piece if I could cut another from a hole-free section of the fabric. I was tempted to pack it away for a while, but I pushed ahead and sewed the seams so I could at least try it on and see if the pattern needed adjustment – which it did.

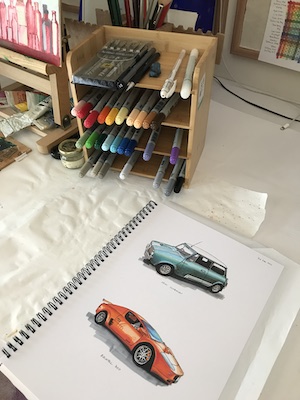

So this is not the blog post I was planning. There’s not been a lot of blog-worthy activity here lately. I’ve made serviceable but unattractive things like a brush holder and sleeve protectors for painting. I’ve reorganised art supplies and given away most of my macrame materials to a friend.

It feels like many months since I did any weaving, but it’s only been about five weeks. I had a strong feeling I needed a break when the 8-shaft course was done. Since then I’ve occasionally looked at my looms and all I can think is I have too many woven items needing homes. I don’t have the energy to sort out selling them though the Guild, let lone on my own. Maybe I should only weave items I need. Well, that wouldn’t be much, and how could I then justify having an entire room dedicated to weaving? Especially when I’m doing more art now and need more space for that.

Such are my thoughts, but then I remind myself that only five weeks have passed and I probably just need more time to regain my enthusiasm.