Almost everything crafty and arty here stopped a month ago when my parents caught Covid and at the same time I had a bad case of food poisoning. Mum wound up in hospital and then in a nursing home. When I finally saw her she was in a pretty bad state and it became immediately obvious that we were going to have to find a better nursing home. After a lot of emotional turmoil, encounters with amazingly compassionate and helpful people, and way more running around than I’m used to, Mum is in a good home. We still have a lot of tasks to get through, but if all goes well the main chunk of work and stress is over.

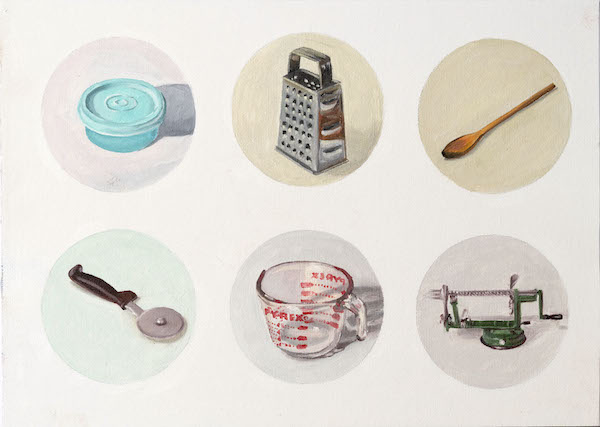

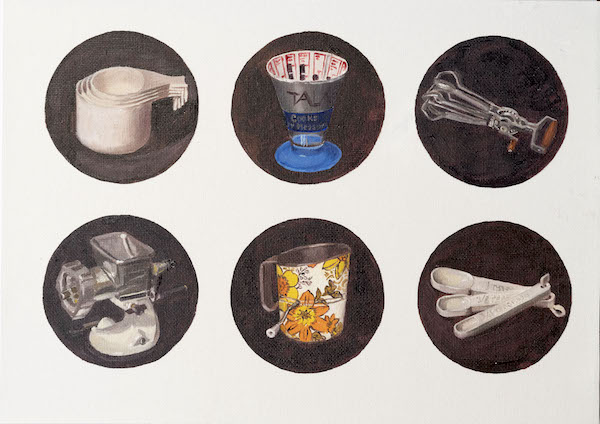

Before this all happened, I’d just finished making frames for the first batch of Nature’s Remnants paintings. And completely forgot to photograph them before I gave them away. They looked good though. I hope I can remember what I did when I come to frame the rest!

In the early days of the drama, I ordered a French dip pen, nibs and ink set from an eBay seller as a kind of me-present to cheer myself up. I got the usual emails from the post saying it had arrived, but there was no sign of it. So I reported it missing, and they called and said it had been delivered 3km away. They said they would try to retrieve it, but I suspect they never tried, it being a very busy time of year for post.

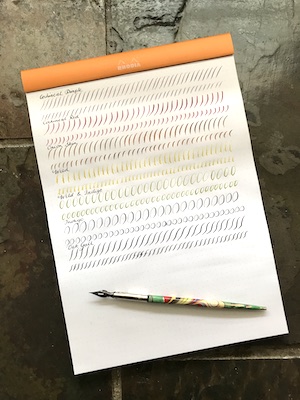

So when I’d given up on them and requested the seller seek compensation, I used a rare free morning to go into Zeta Florence and buy the set full price. It was, after all, supposed to be a cheer-me up treat. Trying out the different nibs and a non-natural source ink was interesting. The ink doesn’t like the notebook I’ve been writing and experimenting in – it bleeds drastically. The nibs are very different, some good for tiny writing, some better for larger. The handle was the main practical reason to buy the set because the handles I’ve got have rusted. I didn’t know I was supposed to remove the nib before washing it.

I also succumbed to a ‘flex nib’ fountain pen sold by the same eBay seller. I’ve been watching YouTube videos about fountain pens, and everyone seems to regard this one (Noodler’s Ahab) as smelly and contrary. The smell – some kind of biodegradable resin – reminds me of old 70s textbooks, but is faint enough not to bother me. The pen did stop working briefly, but I think that had to do with it having only a small amount of ink left in it at the time. It does make a nice variable line, and I think I’ll have fun seeing what I can do with it.

My interest in fountain pens came out of wanting to write and draw with ink while watching tv with less risk of ink drips and spills. I dug out my Lamy pen, which I used as my book signing pen. I’d changed the nib to ‘medium’ because a thicker line is better for autographs, but found that wasn’t so great for drawing and writing. So I bought a ‘fine’ nib and replaced it. Then I found two older Lamys – one of which had an ‘extra-fine’ nib – so that’s also been adopted as a drawing pen.

Paul dug up a fountain pen that was a gift and gave it to me, so I now have five fountain pends. I don’t intend to become a fountain pen fanatic. I admit I’ve looked up when the next Pen Expo is on in Melbourne (November 2023), but only with the thought of selling my oldest Lamy.

The only other bit of craft has been a little bit of sewing. I’d already cut out the pieces of a shirt before the drama started, and I took advantage of a few moments I had time and energy to put most of it together. And earlier this week I suddenly decided I needed to make Mum a fidget blanket. I’ve signed up for another Maiwa course and have been gathering materials and tools for that, but it doesn’t start until January.

Ah, 2023. I’ve had a lot of thoughts about next year too, but that should go in another post.