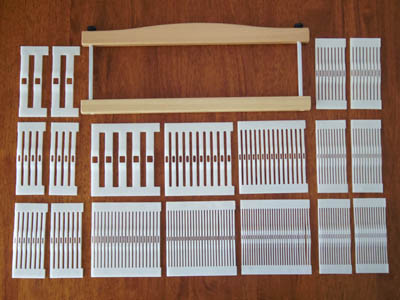

Paul and I tend to throw ideas around for possible presents as birthdays and Christmas near. (Well, okay, I do this and then mostly have to nag Paul for ideas for him.) This year one of mine was an Ashford Vari Dent Reed for my Knitters Loom.

While the advertised use is to weave with different thickness of warp at the same time, it wasn’t until I had some other ideas for how it could be used that I decided I wanted the kit. Some of these idea I tried a few weekends ago, with not much success, I admit, but in doing so I stumbled upon something rather cool. Trouble is, to do this other cool thing would require several of the narrower heddles in the same size, and it doesn’t look like you can buy the Vari Dent heddles outside of the full kit. I’d have to buy four kits in order to get the number I want, and that would be a tad expensive – especially for a concept I haven’t confirmed is going to work yet!

Still, I haven’t given up on the idea. There’s got to be another way. Maybe I can make my own heddles somehow…

Perhaps because it was a birthday present idea, I didn’t do my usual research and inspiration seeking beforehand. When I did, I was surprised to find no YouTube videos – not even by Ashford – for the Vari dent reed. A search for ‘vari dent blog’ brought up very little, as did a search in Google Images. I found two projects on the Schacht Spindle Company website for their version. Ravelry brought up four results for ‘vari dent’ and more if I typed ‘variable dent’, which included other brand’s versions. Weavolution produced two projects in Weavolution, both using a Saori loom.

These scant results did at least flag that some weavers had issues with different rates of warp stretch from using different warp yarns, resulting in uneven fabric. This is a potential problem even when using the same weight yarns made by different makers anyway. One weaver cleverly used this tendency to create a ruffle, and it could be used to make seersucker fabric without the need to felt.

I’ll keep thinking and playing and browsing the internet. In the meantime, I’ve warped up the Knitters Loom with a simple natural wool warp and I’m weaving plain sections of natural and taupe yarns, with the idea of producing some fabric I can sew into a garment. No idea what kind of garment yet.

Oh, and I should mention a little issue I had with the Vari Dent, too, in case anyone else has the same problem.

One of the heddles that was already in the frame was a bit wonky at one end, I suspect by being shipped with the heddle in the frame and the frame screwed together too tightly:

Two of the slots were completely closed at the centre point – the tines jammed together – which would have meant any yarn going through them would be quickly worn through. Of course, Paul not being a weaver, he didn’t notice or know it would be a problem, so it wasn’t until I received the gift and asked him to get it replaced that he took the above photo and emailed the seller.

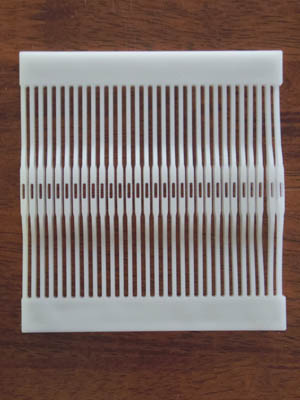

They didn’t reply. After three or four days I decided to risk a little experiment. I boiled some water and quickly dipped the end of the reed in. Sure enough, the plastic softened up. As it cooled I held the tines as close to the correct position as I could. I got this:

Not perfect, but at least there are gaps now.

So I guess my advice is: if you get a faulty vari dent reed and the seller doesn’t respond to a request for a replacement, you could try this. But it would probably mean the seller won’t replace it if the ‘fix’ doesn’t work.