I got to thinking, thanks to the weaving group at the Guild, that it must be possible to weave bead leno on a rigid heddle loom if it has two heddles. After all, it’s possible to weave leno on a table loom so long as you have three shafts, and the extra heddle effectively adds more ‘shafts’ to a rigid heddle loom.

Well, as I learned from an afternoon of experimentation, it’s not that simple.

The first problem is, the heddle on a rigid heddle loom is also the beater. But that can easily be solved by using a lease stick to push each shot into position:

Or use the shuttle:

The second problem may be too hard to explain here. All threads on a shaft loom are controlled like the ‘hole’ thread on the heddle, and that effectively means two heddles gives you only two positions. I just couldn’t get bead leno to work, but I did find a way to do doup leno.

The Ashford Book of Rigid Heddle Weaving contains a project using doup leno using one heddle as a spacer – the warp threaded through slots only. Loops of string tied to a length of dowl behind the heddle are used to get the leno twists. And you can only get leno twists – no tabby.

The method I worked out allows you to have tabby bands between your leno twists, so it’s a slight improvement.

Warping:

1) First, warp the loom with two heddles of the same epi, the rear one with threads in slots and holes, the front with two threads in each slot and none in holes.

2) Place the back heddle in the neutral position and the front on the up position.

3) Then at the front of the front heddle, select the first warp thread that goes through a hole of the rear heddle and bring it underneath its neighbour – a ‘slot’ end – and up again. Tie it to the top of the front heddle with string so that you get a shed just big enough to slip the end of a shuttle into.

4) Continue across until every ‘hole’ thread is tied into position. It should look like this:

Weaving:

1) Place the front heddle in the neutral position and use the rear heddle to get your weaving started with some tabby. Put the rear heddle in the bottom position and weave a shot. It should look something like this:

The string loops allow the shed to open to almost its fullest extent.

Now place the back heddle in the up position and weave a shot. It will look like this:

The string loops will be loose enough to pull under the ‘slot’ threads, allowing the ‘hole’ ones to move into the up position. Again, the loops allow the shed to open to almost it’s fullest extent.

2) For the leno twists, return to the position the heddles were in when you tied on on the string loops, with the front heddle in the up position and the back in the neutral position, and slip the shuttle through the shed. It’ll be a tiny shed, so you’ll have to work the shuttle through close to the string loops.

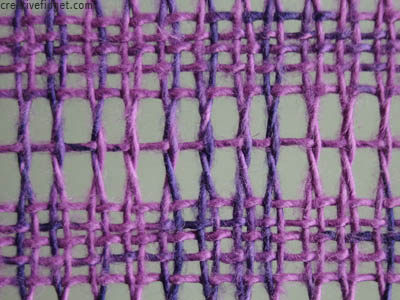

The loops should have twisted pairs of threads around each other. The resulting leno shots spaced between tabby should look like this:

3) Now return to tabby weaving.

I used silk for both warp and weft, and the slipperiness helped the warp threads to slide around each other. Even then, sometimes they didn’t want to go into position. I found two things helped combat this. First I’d run my fingers over the warp threads like they were harp strings. This often flicked them into position. Secondly, to get a good shed for the tabby I’d slip an unused shuttle or warp stick into the gap between the heddles or behind the rear heddle to encourage the shed to open to the fullest.

The leno twist shed was very small and it was fiddly to get the shuttle through. To make it bigger would be to reduce the tabby sheds. I’d rather fiddle with the occasional leno shot than the more common tabby ones. Doing leno this way is still much faster than manipulating the threads individually by hand, which was the object of the exercise, really.