Saturday before last was Printing Day. The projects on my to-do list weren’t the usual stamp carving, wrapping paper making kind, but the fabric printing kind, and there were just two:

Cook Islands T-shirt replica

Try solar dyeing

I decided I liked these small to-do lists that allow me to defeat a category in one day. Well, if all goes to plan…

I didn’t have a particular solar dyeing project in mind at first, but ideas soon came to me. One was to make gifts to take os. At first I wanted to print on thin cotton shawls, but I didn’t want to get stuck with lots of time-consuming hemming to do. Shawls would be bulky, too, taking up space in my suitcase. But what if I printed on silk? Silk painting was an obsession of mine back in my 20s. I knew you could buy pre-hemmed scarves. I still have some scraps of silk, so I decided to test the solar dye on one. I used a scrap of plastic lace for the stencil:

After iron to set the dye and a wash to test the colourfastness and I had this:

The lace pattern wasn’t as distinct as I’d like, but that wasn’t unexpected as the silk didn’t want to sit flat and there was a bit of a breeze stirring things. The lace pattern was rather fine, too. I figured I’d iron the scarves, pin them to rubber foam interlocking squares to stretch the fabric out a little, and cover and weigh down the stencils with a sheet of clear plastic on top.

A trip to Zart later and I had more solar dye and some pre-hemmed silk scarves. I gathered together some possible stencils and did test prints on more scraps. I tried feathers, punched out paper shapes, string, white board markers scribbled on the plastic sheet and a fan. Unfortunately, where the wet cloth touched the plastic strong blotches resulted and most of the stencils didn’t work:

I decided to try another plastic lace piece with larger holes. I was all out of scraps, so I tried a scarf:

It looked great, but the dye was shiny and sticky and even after ironing and washing it the scarf kept sticking to itself. I put it through a hot wash cycle but that didn’t fix it.

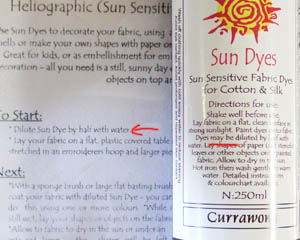

So I looked at the instruction sheet I’d picked up when I bought the first bottle of dye. It says ink is meant to be diluted 50/50 with water. But I’d read the instructions on the bottle and was sure it said the dye ‘may be diluted up to’ 50/50, so I had figured no dilution would mean a strong colour. Turns out I was right:

The next scarf I dyed I wanted a paler blue so I had diluted it anyway. I used lots of metal rings to make pale circles. By then there was enough wind that, despite weighing things down, the rings moved. I tried spritzing the scarf with more diluted dye and got more rings but less contrast.

I didn’t love with the result so I decided I’d overdye it.

By then the sun was getting too low in the sky so I packed up. I was pretty disappointed that I hadn’t finished one project on my to-do lists that weekend (the flanelette blanket fix wasn’t on any). But I figured I’d started my weekend halfway through Friday, so I could spend the next morning doing more solar dyeing… if it was sunny enough.

As it turned out, it was. I started early and I put what I’d learned to good use, deciding to stick to the lace as my stencil. I did a red scarf, another blue one, a grey one and I overdyed the rings scarf from the previous day. I had quite the process line going, ironing, washing and hanging the previous scarf while the next one ‘developed’. Here are some photos of them on the line:

Yeah, I was pretty pleased with the result. Here’s a close up of the overdyed scarf:

You can still see the rings, but the way the blue and black interacted looks fabulous. I put a lot of effort into smoothing the first three scarves when painting the dye on, but I let the grey one stay wrinkly.

However, the red dye, though diluted at 1:1, is still a teensy bit sticky. A little of the silkiness of the scarves has been lost at that ratio. The grey scarf, dyed at 1:4 dye to water has come out the softest.

So it seems that if I want to dye silk, the stronger the colour the more detrimental it is to the fibre. I should aim for a diluted effect. I don’t mind this too much – I like how the blue scarf almost looks like denim that’s had a pattern bleached into it. I’m going to get a few more silk scarves and make a few more lace print scarves. Perhaps in purple, green and brown – and see how pale a blue I can get, too.

As for the Cook Islands tshirt? Well, that turned out to be a fizzer. I tackled it the following weekend, but found the fabric ink just didn’t coat the stamps thickly enough to make a good print.

I figure it would be easier to take a photo and have it printed at Cafe Press or some similar site.

So with that project abandoned and solar dying well and truly tried out, I could declare the Printing category defeated.