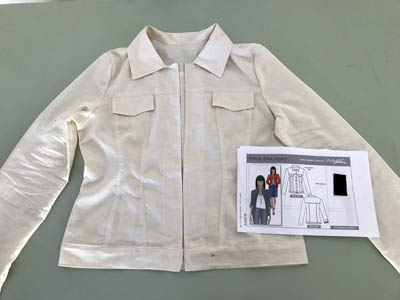

These days I like to make a calico version of sewing patterns I haven’t tried before, so that’s where I started in my quest to reduce the fabric stash. Over three days, I traced off the size 12 version of the Style Arc Stacie denim jacket pattern, cut out all the pieces in calico, then sewed them together. What I wound up with a jacket that was just a bit too small around the chest and hips. I wasn’t surprised about the hips – I am wider there – but I was a bit perplexed by the general fit of the chest.

When I laid the jacket out flat I realised why. The fronts don’t even meet. It’s not just that there’s no allowance for boobs, the back is wider than the front.

I kinda wish I’d known this before I’d bought the pattern and spent three days making a calico version. Though I’d be much more annoyed if I’d not made a calico, and had cut into my fabric.

Well, I do want to be able to button up jackets on cold days. The front is made up of several pieces and to adjust the pattern would be really complicated, so I moved on to option two: make a pattern from a 20+ year old shirt I already have and love.

Over two days I carefully traced off the pattern pieces, using calico so I could easily spread the fabric into corners where I couldn’t arrange the shirt to lie perfectly flat, and sewed them together. I’ve only ever done this with tracing paper before, and I think calico worked better. I used longest stitch on my machine so the seams could quickly be pulled out. A few adjustments were needed, and the collar was especially tricky, but eventually I had a mostly made up test shirt to try on and confirm it fit right. Then I pulled out all the seams and cut out the pieces in corduroy.

The sewing went well. Whenever I needed to work out what order to work in I just referred to the original shirt. Finally I had everything but the buttons and buttonholes done. Hmm. Buttons. I’d like to add jean’s style rivet-attached shank buttons like on the original shirt, but I learned from the black denim skirt I made a year or two ago that the only DIY ones you can get are so low quality they come apart again with very little pressure. So I had no choice but to use sew-on shank buttons.

Of course, despite having a big divided plastic storage container full of buttons, there was nothing suitable. I searched online shops but the only metal shank buttons I found were at Spotlight, and I didn’t want to wait weeks and weeks for them to arrive. So I figured it would remain button-less until I had more than one reason to schlep across town – which was likely to be sooner than Spotlight delivery times because I expected the next project on my to-do list to require supplies.

And indeed it did. So by week’s end I had the shirt finished:

I wore it that day, and found it just as comfortable as the original. It was quite a journey getting something made out of the corduroy, but at least I now have a pattern I would happily use again.