I’ve been cutting strips out of the flannelette scraps for weeks now. I started out using a self-sharpening quilter’s cutting square and a rotary cutter, but after a couple of hour-long sessions my hand began to hurt – my right hand from pressing down with the cutter and the left from pressing on the square to hold it still.

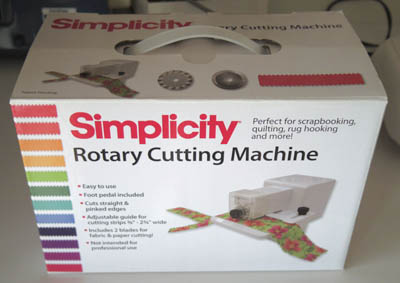

Looking at the amount of cutting still to do, I nearly gave up on the whole idea. Instead I delved into the back of the sewing cupboard and found this electric rotary cutter:

I’d used it before, and knew the resulting strips are in no way as neat as those cut with a rotary blade and square, but perfect edges don’t really matter for rag rugs strips. The cutter also has some annoying tendencies, but I eventually worked out how to minimise them.

It’s not faster than doing it by hand, but my hands didn’t complain – and my back didn’t so long as I kept sessions down to half and hour to an hour. After a couple of weeks I had got through over half the scraps and had enough for a large rainbow inspired rug, a ‘brights and whites’ rug, and a smaller mat of earthy colours.

I stopped then, figuring that I ought to work out whether I hated weaving the stuff before spending months cutting it all up. In the meantime, I’d bought $400 worth of rug cotton in six colours plus black.

Purchased a bias binding jigamething from Spotlight.

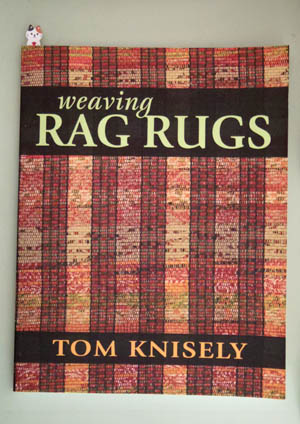

And consulted this book:

I wanted to get an idea what width of rug I should warp up for. Tom shows the results of a test he did, where he bought a yard of several kinds of fabric and wove it on the same warp, to see how many inches of fabric he got.

This would be a useful rough guide if he’d mentioned what the fabric width had been to begin with.

Flannelette on the Spotlight website is 112 cm wide, so I decided to gamble that it was sold at the same width in the US, too. Based on the guess that his fabric had been 112 x 91 cm. Doing the math, I worked out this was pretty close to 100 x 100cm. I laid out strips until I’d covered that much area of my dining table, then weighed them.

So to know how big a rug could be, I can take the weight of all the strips for it and divide that by the weight of the 100 x 100 cm batch. Then I multiply the width by length of Tom’s sample to get the square meterage of his sample rug. Then I multiply the weight of my batch by the square meterage to get the square meterage of my potential rug.

All I need to do then is divide the square meterage of my rug by the width of the rug I want to make, and I get the length. Or divide the square meterage of my rug by the length I want to get the width.

To be honest, I won’t really know if this will work until I try it. I might be wrong about the width of Tom’s fabric. I might have the math all wrong. But I’ve got the weight of 100 x 100 of flannelette and the weight of the rags for a rug, so after the first rug I can use those numbers to make a more accurate square meterage number to work out the slightly less rough size of future rugs.

But before I get to that point, I need to sew together a LOT of strips, use the bias binding jig to help me iron them into tubes, finish the jacket I’m weaving on the Lotas, and warp the loom.

It’s slow going, but I’m in no rush.