Ever since Paul gave me the Vari Dent reed my brain has been buzzing with possibilities and wrestling with its limitations. I’ve been looking for ideas, too, mostly in vain. Searching the internet for anything to do with variable dent reeds has had me scratching my head at how little there is to find.

There are three versions out there:

The Ashford Vari Dent.

A search on the site brings up only three entries. One is a link to Wheel magazine, because there is an article in last year’s issue, one is a news item announcing the reed with a few photos, the last is just a link to the SampleIt Loom. There’s one forum discussion on Ravelry begun 19 months ago.

The Schacht Variable Dent Reed doesn’t appear to have a page dedicated to it on their site, but a search for it brings up several three-year-old blog posts, some including projects. A search on Ravelry brought up an announcement of it’s release from four years ago, which also brought my attention to another version made by Majacraft…

The Kromski Weaver’s Choice Heddle is a slightly more complex and flexible system that seems to have been available for a year now. There’s a great video on how it works at the link above. It’s interesting, but not suitable for what I want to do.

The ideas I want to explore require several reed sections of the same size. I emailed Ashford to see if I could buy more and they replied that they aren’t selling reeds individually. Thinking hard, I came up with two other ways to get hold of what I needed (other than buying two or three more Vari Dent kits). The first was to get my own heddle sections made. The second was to buy a full size reed, remove the frame and chop it up.

The first idea looked like the best one, as I have a friend with access to a 3D printer. But after chatting to her I changed my mind. We agreed laser cutting would be better and she suggested a company. I was a bit intimidated, and leaned toward buying a reed to cut up, but came back to laser cutting after considering how difficult it could be to cut it up. So I worked up some files in Illustrator and, since I could do what I liked with the design, I made the heddle pieces even narrower than those supplied in the Vari Dent kit.

I sent off three different sizes of a single heddle as a test: 10 dpi, 12.5 dpi and 15 dpi. This was delivered a few days later:

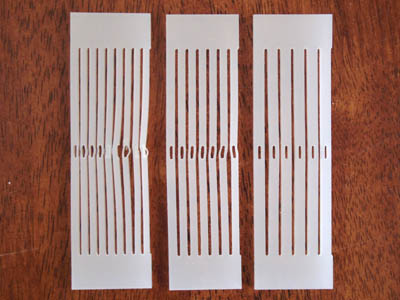

The acrylic had melted and distorted thanks to the heat generated by the laser. A few emails to the tech guy and we had a possible solution. A week later these arrived:

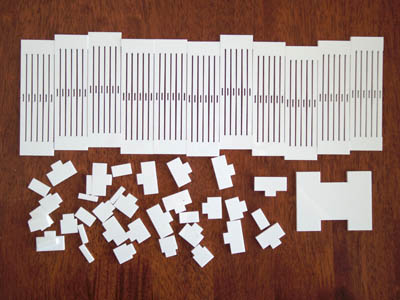

Almost perfect. The slot gap on the side of each heddle is quite narrow, and makes a half size gap when the heddles sit against each other, but when I warped up the loom it wasn’t a problem. However, my reed hook was a bit thick for the holes, and on the second project one of the reeds broke as I pulled the yarn through. Fortunately I had spares made – and Paul made me a thinner hook out of flattened wire.

The other shapes shown are spacers to use between the reeds, and a wraps per inch guide that I whipped up only because there was a space free.

So far I’ve done one and a half scarves, confirming two of my ideas work. I have a few more ideas to try. When I’m done experimenting I’ll do a separate post – or posts – with photos. And I might see if there is another way to do what I’m doing using just the reeds from the Vari Dent kit, too.