There’s something that tickles me about how the actual weaving of rag rugs is so fast. There is SO much preparation, and then BAM! a couple of hours more and the rug exists. (Mostly. There’s still hemming and washing, of course.)

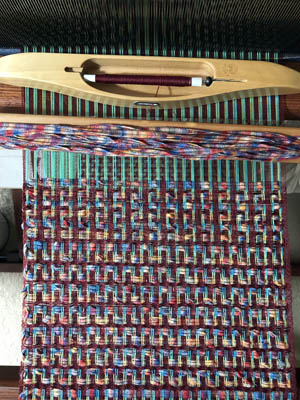

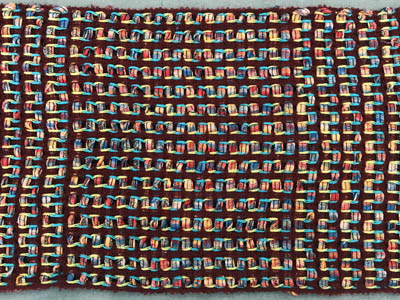

The Aqua Rug turned out shorter than I’d intended. When sewing together the rags I had an older batch of mixed rags already sewn together, a few misc strips, and two newer batches of unsewn strips in the same colourway. Instead of cutting the already sewn strips apart to mix in the new ones, I added only the misc pattern strips, then sewed the two similar colours together. My aim was to use two shuttles to weave alternate rows of old-mixed and new-similar batches.

This made for only slightly more complicated weaving. It also meant I ran out of the old batch before I got to last quarter of the new, and I wound up with a shorter rug than I’d planned. I’m wondering, now, if I should have woven two new-similar rows for every old-mixed one. Too late now. The unused strips went into the box of leftovers.

The Blue Rug was one big batch of evenly mixed pattern, so I could just wind it onto a single shuttle and weave to the very end. Despite this, it really felt like it took much longer. Partly because I was weaving in shorter sessions, and because it wasn’t much shorter than it should be!

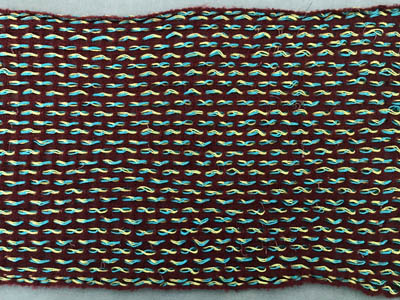

Since the Aqua Rug came out shorter than planned, I had a lot of warp left over. I decided to try weaving with t-shirt fabric strips. This came out much nicer than I expected and not needing to fuss with folding in the edges of the strips made it SO much faster. It was only slowed by having to stop and cut up more old garments. The down side is that no matter how you cut up t-shirts or leggings, you’re going to have corners or seams creating lumps. I don’t mind this, but it does make for a more bumpy rug and some people mightn’t like that.

I got to thinking, as I wove, that it might be worth taking the time to sew the flannelette strips. Ironing them with a bias tape maker helps by folding in the edges, but I still have to fiddle a lot to get them to sit right when weaving. So I tried that on the next rug’s strips and found that it’s slower than I hoped and chews through a lot of thread.

I’m at the point, now, where I don’t think I’d take more flannelette rags even if they were free. Though it was nice having a source material that was not ‘used’, the prep is too time-consuming and dark colours aren’t common (light colours not being so good for hiding dust and stains). If the fabric comes in larger pieces it is much faster to cut, and if the colour is near to or as dark on the back the edges don’t have to be folded in so long as it isn’t too prone to fraying.

There’s still enough flannelette for five or six rugs, however, so I’m not even going to be looking for fabric for some time!