The Squares Jacket got me thinking about how I’d like some new knits in my wardrobe. Of course, I can’t hand knit any but I could drag out the Bond Sweater Machine. But did I have any yarn that would work? And patterns that wouldn’t be too hard to do on the knitting machine?

The stash presented two possibilities: either I finally get around to dyeing and knitting the 1.5 kilos of cormo yarn, or I combine smaller batches of yarn to get enough for a garment.

The cormo yarn has intimidated me since I bought it, because it is beautifully soft and therefore easy to ruin when dyeing (and I know I’ll have to dye it because I don’t want a big fluffy white garment or blanket), and I know the maker had some trouble getting it to dye evenly.

The smaller batches were a mix of frogged projects and leftover yarn. Some I’d already matched up. But once I removed anything that wasn’t machine washable I had to reconsider those matches. Some were flat colours, others were variegated from previous dye jobs.

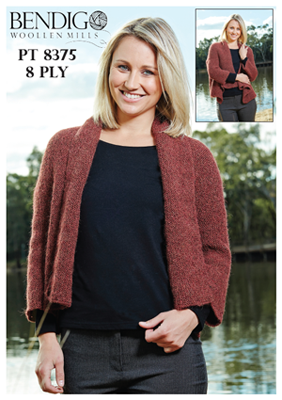

I bought and printed a few patterns and studied them, seeing how well they’d adapt to being knit on a machine. Hand knitters tend to prefer knitting in the round these days, but increases on knitting machines are easier done on the sides, so I have to divide patterns up into smaller pieces and sew then together. The first pattern I looked at turned out to be knit from the top down with raglan sleeves, and trying to convert it did my head in so I abandoned it. I found two more that would work. One was for 10ply, so I decided the cormo would be for that. The other was for 8ply, so it would be for the mixed batch of yarns.

Then a couple of hours dyeing turned into a day of frustrated plans.

The first mistake was mixing up a batch of orange dye by accident, because the label had faded to yellow. I wanted to overdye a blue yarn with yellow to make a variegated green. So I set the orange aside and started again. Only instead of a nice green I got khaki. So I overdyed that with a blue. Which worked but left me with a much darker result than I’d intended.

The dye bath was still very blue so I tipped it into the orange and got a nice forest green. I divided it in half, diluted it and dyed the cormo in two batches. The first batch came out looking great but most of the dye rinsed out and I was left with… various intensities of orange.

So I grabbed the remnants of another blue and some magenta and black sample packs and threw them into some fresh water, divided it into quarters, and dyed the cormo again in hanks of three. It came out… a very pale patchy mauve with dark purple areas and some lingering orange bits.

Which was better. I noticed, as I squeezed out the hanks, that the water beaded off the surface of the yarn. So maybe it still has lanolin in it. Well, I don’t mind the mauve-with-orange bits result, and I don’t seem to have ruined the yarn, and the blue-green is okay, so ultimately I got what I needed.

Now for the machine knitting bit…